Why Precision aluminum casting continues to dominate in metal component design

Just How Factory Services Enhance Manufacturing Performance and Top Quality in Industrial Applications

Shop services play a vital function in enhancing production efficiency and high quality across numerous industrial applications. By applying sophisticated metal casting strategies, these solutions guarantee elements are made with accuracy and consistency. This not only lowers preparations but also lessens waste, cultivating better partnership between factories and makers. The effect of top quality parts on operational efficiency raises important questions regarding the future of industrial production. What advancements lie in advance in this evolving landscape?

The Function of Factory Providers in Streamlining Manufacturing Processes

Shops commonly supply expertise in alloy advancement, making it possible for producers to use sophisticated materials that enhance item efficiency. The partnership between factories and makers fosters a better understanding of manufacturing demands, leading to optimized processes and enhanced product designs. By leveraging shop services, producers can accomplish greater adaptability, adjust to altering market demands, and keep competition in the industry. In general, the function of factory solutions is essential in helping with a much more cost-efficient and reliable manufacturing landscape.

Advanced Technologies in Shop Procedures

Cutting-edge innovations are changing factory operations, markedly improving efficiency and precision. Automation plays a necessary role, with robot systems streamlining recurring jobs such as molding and material handling. Additionally, improvements in computer-aided design (CAD) and computer-aided production (WEB CAM) systems allow shops to develop complex geometries with better precision and reduced product waste.

In addition, the assimilation of artificial knowledge (AI) and device discovering boosts quality control by keeping an eye on processes in real-time and predicting potential defects before they occur. Making use of innovative materials, such as lightweight alloys and compounds, further improves the performance attributes of cast items.

Furthermore, 3D printing modern technology is changing prototyping and tooling, enabling for quick personalization and minimized lead times. Collectively, these innovative innovations not only raise production efficiency yet likewise ensure that the last items fulfill stringent top quality standards, positioning foundries at the leading edge of modern-day commercial applications.

Reducing Lead Times Via Efficient Foundry Practices

Reliable foundry techniques play an essential duty in reducing preparations within production atmospheres. By carrying out structured production processes and advanced scheduling techniques, manufacturers can enhance process and optimize resource allotment. These enhancements not only accelerate result yet additionally contribute to general functional performance.

Structured Manufacturing Processes

Streamlining production processes is crucial for reducing preparations in the production market. Reliable factory techniques, including maximized process and source monitoring, play a critical function in achieving this objective. By lessening waste and enhancing communication amongst teams, factories can considerably enhance their operational performance. The application of standard treatments additionally contributes to constant quality and faster turnaround times, allowing manufacturers to respond even more swiftly to market demands. Additionally, the assimilation of sophisticated innovations, such as automation and real-time surveillance systems, aids in recognizing bottlenecks and facilitating prompt interventions. Generally, a focus on streamlined production procedures not just accelerates lead times however also boosts the overall competitiveness of commercial applications, guaranteeing that products fulfill client expectations efficiently.

Advanced Scheduling Techniques

Reliable production procedures normally lead makers to discover advanced scheduling techniques as a way to further reduce preparations. By employing advanced algorithms and software application, factories can enhance workflows, straightening production routines with need projections and resource schedule. Methods such as Just-In-Time (JIT) scheduling minimize supply costs while ensuring timely product distribution, consequently boosting functional effectiveness. Additionally, incorporating real-time information analytics permits shops to anticipate possible delays and change schedules proactively. This versatility not only improves procedures yet also improves total efficiency. In addition, collaborative preparation with vendors and customers can promote a more integrated supply chain, more decreasing preparations. Inevitably, these advanced scheduling techniques equip factories to attain higher effectiveness and premium quality in their production processes.

Ensuring Precision and Quality in Metal Casting

Guaranteeing accuracy and quality in steel spreading calls for a precise method that encompasses every phase of the manufacturing procedure. This process begins with careful style and design of the mold and mildews, ensuring they can stand up to the liquified steel's temperature and pressure. The option of top quality raw materials is crucial, as pollutants can jeopardize the final item.

When the materials are prepared, precise temperature level control throughout melting and pouring is basic to achieve the wanted properties in the actors steel. Monitoring solidification and cooling prices more assurances dimensional accuracy and surface area finish.

Quality assurance practices, such as non-destructive screening and assessment, are important to identifying defects early while doing so. Precision aluminum casting. In addition, using experienced workers that comprehend the subtleties of metal spreading adds substantially to maintaining high standards. Generally, these practices jointly enhance the dependability and performance of cast parts in different industrial applications

Minimizing Waste and Maximizing Resource Usage

In addition, reusing scrap steel within the factory itself can significantly lower waste, changing by-products right into useful sources. Lean producing principles likewise add to waste reduction get redirected here by simplifying processes and removing unneeded actions, bring about a lot more efficient procedures.

Routine upkeep of tools assurances peak efficiency, preventing breakdowns that can result in wasted products. By focusing on these techniques, factories not only reduce expenses however likewise add to sustainable practices, aligning with the expanding need for eco responsible manufacturing approaches in commercial applications.

The Competitive Benefit of High-Quality Parts out there

Premium components provide a considerable competitive benefit in the foundry market, where precision and toughness are extremely important. Producers that prioritize exceptional his comment is here products and workmanship can boost item efficiency and integrity, resulting in increased customer complete satisfaction. This advantage is specifically noticeable in sectors such as auto and aerospace, where component failing can have tragic consequences.

Top quality parts often result in lower upkeep costs and extended item life expectancies, which can be attractive marketing points for possible customers. As market needs grow for lasting and reliable innovations, the focus on top quality becomes a lot more critical. Companies that invest in high-grade factory services not only improve their production processes but also differentiate themselves from rivals that may compromise high quality for price financial savings. The commitment to top notch parts inevitably equates right into a stronger market position and long-lasting service success.

Frequently Asked Inquiries

What Types of Products Do Foundry Solutions Usually Function With?

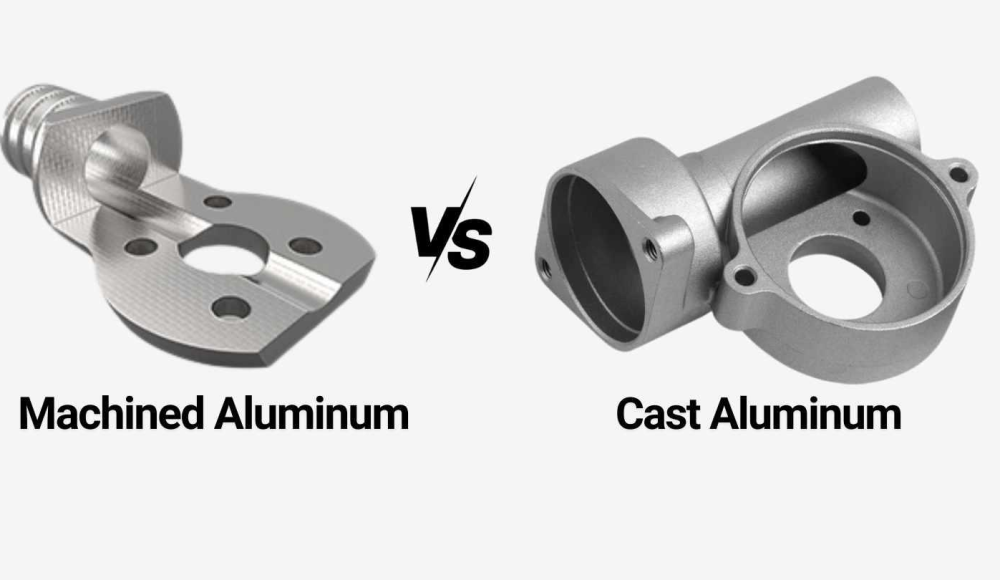

Foundry services generally deal with metals such as light weight aluminum, iron, brass, and steel, along with different alloys. They additionally manage materials like ceramics and composites, satisfying diverse industrial demands and specs in making processes.

Exactly How Do Factory Solutions Impact Overall Supply Chain Management?

Factory solutions substantially boost supply chain management by enhancing product sourcing, reducing lead times, and ensuring constant high quality. Their ability to supply tailored solutions promotes cooperation among stakeholders, inevitably improving total functional efficiency and responsiveness in production.

What Industries Benefit Most From Factory Services?

Industries such as vehicle, building and construction, aerospace, and customer items substantially profit from foundry solutions. These industries count on precision spreadings to fulfill strict top quality requirements and improve their total manufacturing processes and item efficiency.

Are Factory Solutions Lasting and Eco-friendly?

Shop solutions can be eco pleasant and sustainable, specifically when using advanced technologies and processes - Aluminum Casting Company. Developments such as recycling products, lowering exhausts, and maximizing energy usage add to minimizing their environmental influence in industrial applications

How Can Business Pick the Right Foundry Service copyright?

Business can select the best foundry provider by evaluating expertise, visit this website production capabilities, high quality certifications, innovation used, consumer testimonials, and sustainability techniques while making certain positioning with their details job demands and lasting service objectives.

Foundry services play a necessary role in boosting manufacturing efficiency and top quality across various commercial applications. The collaboration between suppliers and factories fosters a better understanding of manufacturing requirements, leading to optimized processes and improved product designs. Effective shop techniques play a vital function in lessening lead times within production atmospheres. By utilizing advanced algorithms and software program, foundries can maximize process, straightening production routines with demand forecasts and resource accessibility. Business that invest in high-grade foundry services not only enhance their manufacturing procedures however additionally distinguish themselves from competitors that might sacrifice top quality for expense financial savings.